There is an Easy-Laser shaft alignment system for every situation and industry, from the most simple to the most advanced. All systems are designed to be easy to mount on the machines. Vital components are made of aluminium and stainless steel to guarantee reliable measurement values and the highest reliability in even the toughest of environments.

With the XT770 Shaft+GEO you can perform shaft alignment of horizontally and vertically/flange mounted machines, and align machine trains with an unlimited number of machines. You can also measure straightness, flatness and twist of foundation, soft foot, bearing clearance, and more.

Easy-Laser® XT550 is an intrinsically safe shaft alignment system, developed for use in potentially hazardous areas.

Easy-Laser® XT440 is our most basic, app based system. Lets you perform all necessary steps of shaft alignment on horizontal and vertically/flange mounted machines.

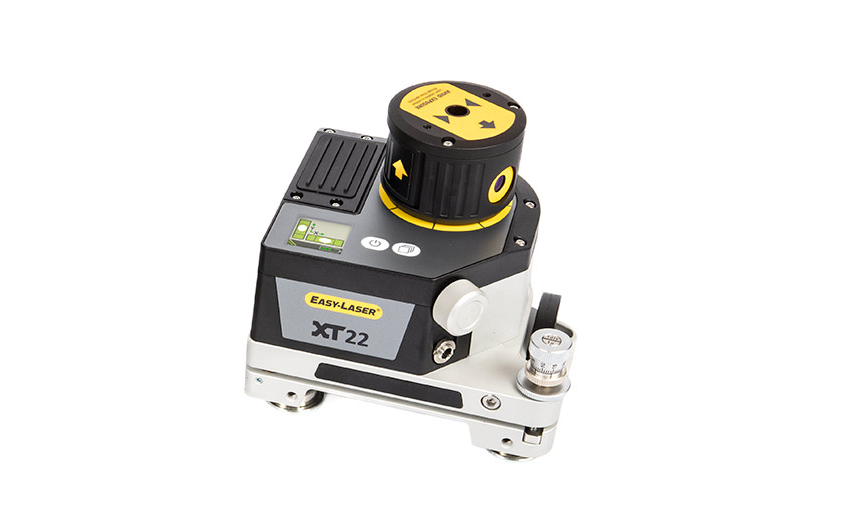

The XT22 laser transmitter can be used to measure flatness, straightness, squareness, level and parallelism. The laser beam can sweep 360° with a measurement distance of up to 40 meters [130´] in radius. The laser head is super stable, but still easy to turn. No need for locking/unlocking screw. The laser beam can be pointed perpendicular to the flatness plane, within 0.01 mm/m [0.01 mils/inch]. XT22 has a fine turning mechanism for the laser head with a gear ratio of 1:1320, which makes it super easy to point the beam at the detector also on very long distances.

The XT20 laser transmitter can be used to measure flatness and straightness. The laser beam can sweep 360° with a measurement distance of up to 20 meters [65´] in radius. The laser head is super stable, but still easy to turn. No need for locking/unlocking screw. The laser head fine turning knob makes it very easy to point the beam at the detector also on long distances (gear ratio 1:132).

Geometric measurement technology spans an extremely wide field. From relatively simple straightness measurements of a member to considerably more complicated right angle measurements of machine tools and checks of turbines for power generation. The Easy-Laser® systems are excellent for taking all these types of measurements quickly and easily. The universal and intelligent design gives you many application possibilities, because the laser transmitter and detectors are designed to be twisted, turned and mounted in all possible and impossible ways!

We have a complete range of professional tools for belt transmission alignment. Choose between “visual” display on targets or digital display. Regardless which one you choose, the result is reduced pulley, belt, bearing and seal wear. Vibration levels are also reduced. Increased efficiency also means lower energy costs. For these reasons, a belt alignment system normally pays for itself within a few months, regardless of which model you choose.

The XT190 allows even more accurate and efficient alignment of sheaves/pulleys, and is unique to the market in being able to offer digital read off.